Microsoft MB-330 Übungsprüfungen

Zuletzt aktualisiert am 02.02.2026- Prüfungscode: MB-330

- Prüfungsname: Microsoft Dynamics 365 Supply Chain Management Functional Consultant

- Zertifizierungsanbieter: Microsoft

- Zuletzt aktualisiert am: 02.02.2026

SIMULATION

You are a functional consultant for a company named Contoso Entertainment System USA (USMF).

From sales order number 000720, you need to ensure that a product named Projector Television is delivered directly to a customer.

To complete this task, sign in to Dynamics 365 portal.

A warehouse picks and ships product.

The warehouse completes work immediately upon automatic release to the warehouse.

You need to configure waves to allow for automatic work creation.

What should you do?

- A . Automate wave creation and process the wave automatically at threshold.

- B . Select the wave template and process the wave at release to warehouse.

- C . Select the wave template and attribute to automatically process.

- D . Automate replenishment and process the wave at release.

A distribution company is implementing Dynamics 365 Supply Chain Management.

The company plans to expand into providing trucking services for its primary distribution center. The company may expand into other locations later.

All vehicle maintenance will be performed at standardized intervals to meet trucking regulations.

The vehicles must be established on the maintenance schedule at the distribution center. The fleet manager requires all vehicles to be grouped together by location for the distribution center and by sublocations for any hubs.

The company requires the following implementation:

• Sublocations must inherit the maintenance schedule.

• Non-vehicle assets must not inherit the maintenance schedule.

You need to configure the system to meet the requirements.

What should you configure?

- A . asset counters

- B . functional location types

- C . work orders

- D . asset service levels

Topic 7, Coho Vineyard & Winery

Background

Coho Vineyard & Winery is a parent company that has two subsidiaries: Coho Vineyard and Coho Winery. Coho Vineyard is based in Medford, Oregon. The vineyard grows the grapes and then produces and bottles the wine. Coho Winery, based in Grants Pass, Oregon, distributes packaged wine to businesses and consumers. The winery sells imported cheese and olive oil in addition to the wines.

Current Environment

• Coho Vineyard & Winery requires financial reporting from both Coho Vineyard and Coho Winery. The parent company consolidates financials in a third-party tool.

• Coho Winery currently manages inventory and financials on spreadsheets separately from the parent company.

Inventory and warehousing

• The entire warehouse is temperature controlled. A refrigerated section of the warehouse is used for items that require colder storage.

• The items do not have fixed locations in the warehouse.

• Coho uses smart numbering for cheese items today.

The items start with Ffor France and iVfor United States such as the following:

o F11234 = French cheese

o U14567 = US cheese

• Currently, wine does not use smart numbering.

• Inventory is valued at First In, First-Out (FIFO).

• Olive oil has a 12-month shelf life.

• WineA is expensive and not regularly stocked in the warehouse.

• WineB must be in the refrigerated section of the warehouse.

• WineC is non-refrigerated wine and is the majority of inventory in the warehouse.

Vendors and procurement

• Cheese is purchased from vendors in two countries: France and United States.

• Non-cheese items can be purchased from vendors in other countries or regions.

• Olive oil is bought and sold in full cases of six each.

• When Coho Vineyard produces more wine than expected in a season, rebate programs are offered to any company whose monthly purchases exceed $5,000.

General

• The Coho Vineyard & Winery parent company, as well as Coho Vineyard, will not be considered in the implementation of Dynamics 365 Finance and Dynamics 365 Supply Chain Management for Coho Winery. They plan to implement them as separate legal entities in the next five years.

Inventory and warehousing

• Items musl be renumbered in the new system.

• Separate item numbers must be used for each imported item for use in simplified reporting by source country or region.

• Advanced Warehouse Management capabilities must be enabled in the new system.

• Each bottle of wine has a single item number.

• The vintage of each bottle will change annually and may affect the cost of the bottle. This cost must be tracked by year.

• Some bottles of wine require refrigeration. The system must automatically define where items must be stored in the warehouse.

• Wine must be grouped in a hierarchy such as the following:

o Red

■ Cabernet

• Me riot o White

■ Chardonnay

■ Pinot

• Inventory value must be stored at each month end.

• Each month, the olive oil on-hand inventory is evaluated. Anything with less than six months left on the shelf life is sold to a discount retail store. If less than 90 days remains for the shelf life, then the olive oil is donated or destroyed.

• At least 20 cases of olive oil and no more than 50 cases are on hand and not reserved for upcoming customer orders.

• WineB must be refrigerated.

Vendors and procument

• The cheese smart numbering system will not be used in the future, instead, the system must use standard configurations to ensure the correct cheese items are used for the correct country or region when ordering.

• Olive oil must be managed in full cases only, although the inventory cost must be calculated as eaches.

• Should any bottle of olive oil be broken within a case, the eaches will be sold at a discounted price.

• Vendor rebates must be calculated and submitted for a claim.

• Rebate programs are passed on to the retailers selling Coho Winery wines. The rebates must be claimed from Coho Vineyard.

• Purchase orders (POs) must be maintained online with tracked changes between the vendors and the buyers.

• The controller decides WineA must not be held in financial inventory on the Coho Winery books. The winery makes an agreement with the vendor that WineA will be owned by the vendor until a later date.

• Vendorl sends bulk shipments. Coho Winery does not always have enough warehouse staff to receive inventory. The company requires Vendorl to send advanced shipping notices (ASNs).

• The operations coordinator must schedule inbound loads. The company requires automation of inbound load creation where possible.

Issues

• The warehouse is at maximum capacity. Empty bin locations are not always available. The warehouse manager wants to establish fast moving locations for WineB on the floor and refill locations from higher rack storage.

• Coho Winery recently conducted an internal audit risk assessment. The risk assessment found that inventory value reports were stored in spreadsheets. The spreadsheets can easily be edited and lack controls.

• After olive oil is counted, multiple cases are destroyed due to shelf life. The inventory planner must determine if a new PO should be placed for olive oil.

• The vendor rebates claims are often rejected because the claims were miscalculated by not including discounts.

• The purchasing manager receives multiple complaints regarding POs:

o Issue 1: PO changes are not accepted and confirmed, resulting in out-of-stock issues,

o Issue 2: Vendors do not have control on responses to POs. Instead, thevendors relv on emails.

You need to configure cheese smart numbering to meet the requirement.

Which component should you configure?

- A . Country of origin

- B . Filter codes

- C . Purchase agreement

- D . Default order settings

A company uses Planning Optimization and first in, first out (FIFO) inventory valuation. The company also has special requirements on sales margins. Company policy states that marking must be a single issue that is fully marked against a single receipt, regardless of quantity.

What should you do to respect marking when planned orders are being firmed? Select only one answer.

- A . Allow negative inventory.

- B . Enable Ordered Reserved.

- C . Set the Update marking parameter to Extended.

- D . Set the Update marking parameter to Standard.

- E . Set the Update marking parameter to No.

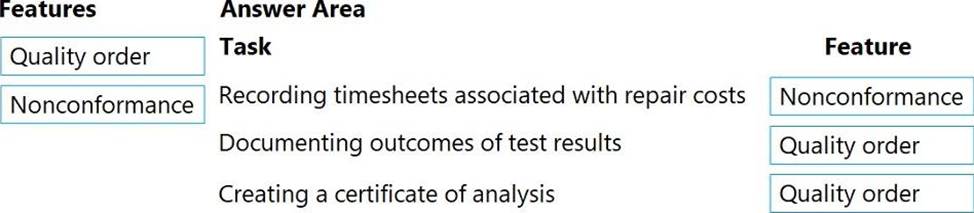

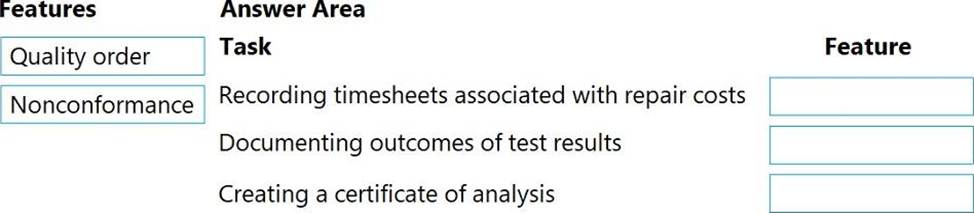

DRAG DROP

A company is implementing Dynamics 365 Supply Chain Management.

The company wants to configure the quality orders and nonconformances for the following tasks:

• Recording timesheets associated with repair costs

• Documenting outcomes of test results

• Creating a certificate of analysis

You need to configure the features for these tasks.

What should you configure? To answer, drag the appropriate features to the correct tasks. Each feature may be used once, more than once, or not at all. You may need to drag the split bar between panes or scroll to view content. NOTE: Each correct selection is worth one point.

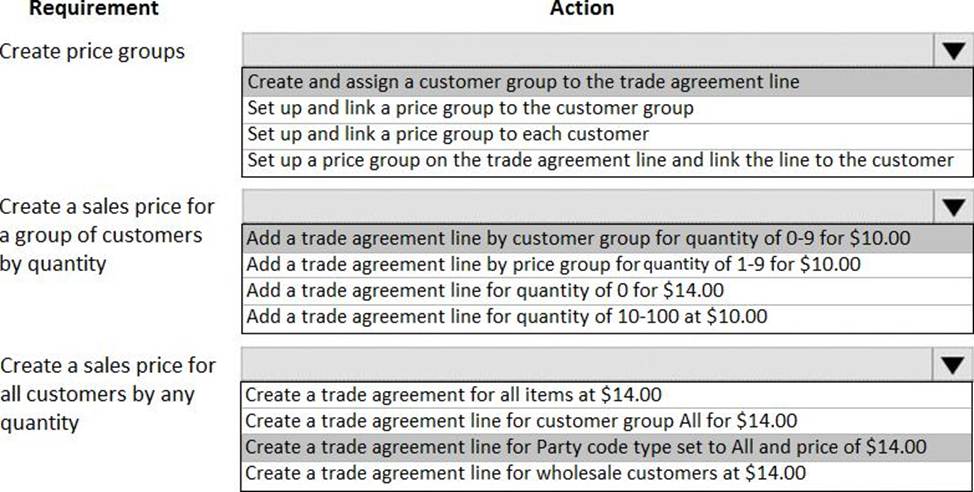

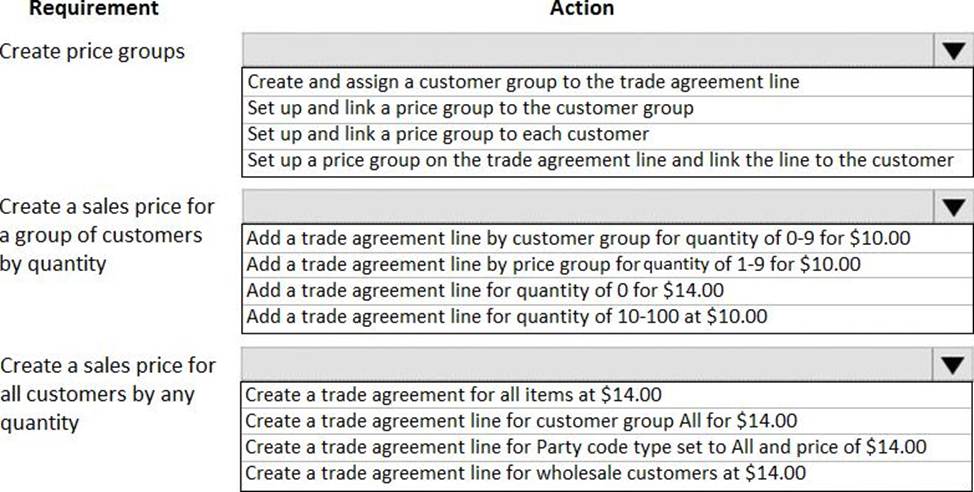

HOTSPOT

You are configuring pricing for a new item.

Wholesale customers must pay $10.00 for order quantities of up to 9 units. All other customers receive a static price of $14.00 regardless of quantity.

You need to configure sales trade agreements.

In Trade Agreement Setup, which actions should you perform? To answer, select the appropriate options in the answer area. NOTE: Each correct selection is worth one point.

Note: This question is part of a series of questions that present the same scenario. Each question in the series contains a unique solution that might meet the stated goals. Some question sets might have more than one correct solution, while others might not have a correct solution.

After you answer a question In this section, you will NOT be able to return to it. As a result, these questions will not appear in the review/ screen.

A company plans to simplify interactions between purchasing department employees and vendors.

You need to ensure that employees are redirected to a vendor’s online store to select items for inclusion on purchase requisitions.

Solution: Create a vendor catalog.

Does the solution meet the goal?

- A . Yes

- B . No

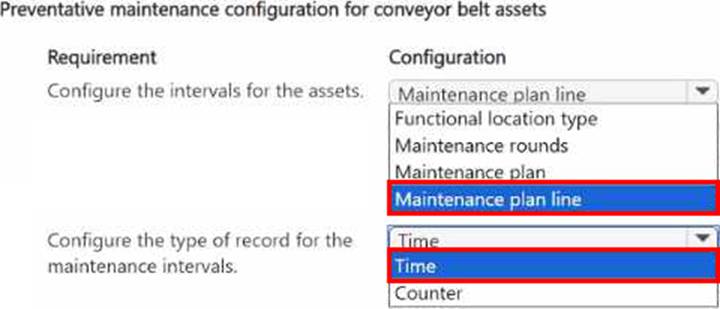

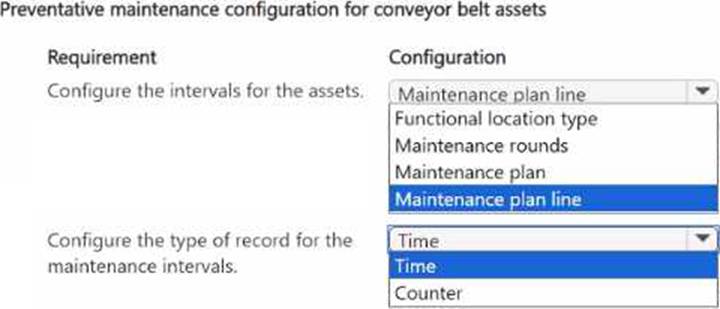

HOTSPOT

A company is using Dynamics 365 Supply Chain Management for its asset management operations.

The company must manage periodic, preventative maintenance for two types of conveyor belt assets.

• One type of conveyor belt asset must be maintained daily for a total of 365 total inspections.

• The other type of conveyor belt asset must be maintained weekly for a total of 52 total inspections.

Preventative maintenance must be consolidated under a single record for all conveyor belt assets.

You need to configure the features for the solution.

Which features should you configure? To answer, select the appropriate options in the answer area. NOTE: Each correct selection is worth one point.

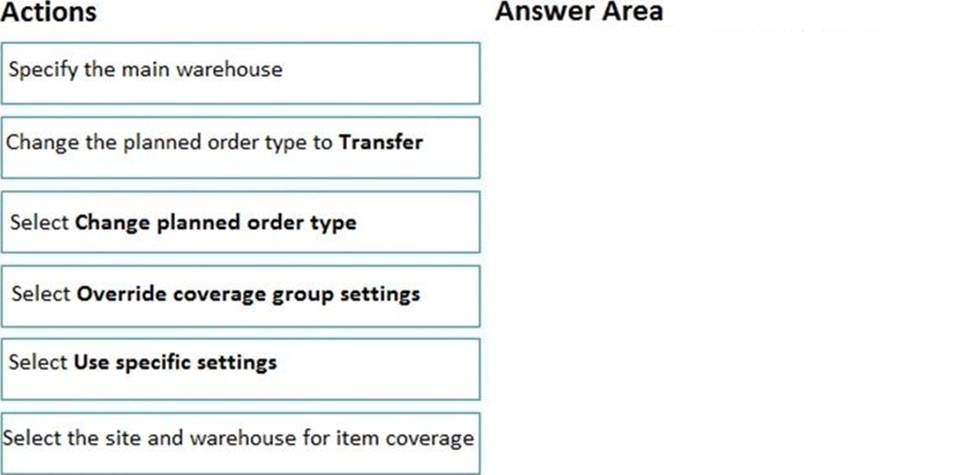

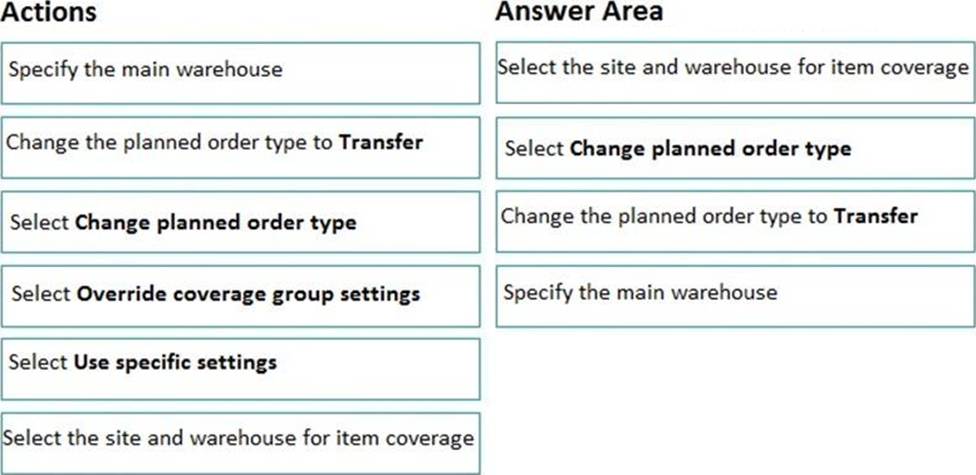

DRAG DROP

A manufacturing company is setting up a new warehouse.

The warehouse must store a product that is currently stored in another warehouse.

You need to create new item coverage for the warehouse.

Which four actions should you perform in sequence? To answer, move the appropriate actions from the list of actions to the answer area and arrange them in the correct order.